Checkmate A1500 Plus – A500+ Build – Part 2

This is part 2 of my write up as I bumble my way through an attempt to move my Amiga A500+ to a new case.

My Amiga has been in storage for a while and I haven’t needed to open it up for a long time. Just after writing part 1 I discovered some corrosion on the A500+ motherboard. I had removed and replaced the built in battery a few years back due to it showing signs of mild leakage . I thought that I had cleaned it all away. Perhaps I didn’t go far enough with my efforts and this is the result.

So before I continue with the Checkmate build it is only sensible to address this damage first. While I waited for the required supplies to arrive I made a little progress.

Putting the Keyboard together

The keyboard will move to a two piece, metal shell. The case is fitted with a pair of angled supports for each end of the keyboard. There are a couple of cut outs for whichever wiring solution you choose. I will be using the 7 Pin Din cable and sockets. The socket is already wired to the 7 pin keyboard connector. No soldering required! Installation is simple but I found that connecting the cable to the socket helps to ensure the socket is positioned correctly while tightening the fixings. The hole in the case is so precise that unless its exactly correct you may not get the cable into the socket. I checked for continuity over the entire length of the cable just to make sure all was well.

Two metal hooks hold the keyboard at the correct height. This could be enough but there are holes drilled into the top of the supports into which you place a couple of retaining screws ( the manual says to use washers but none were supplied ). I found that these should not be over tight. Just enough to stop the keyboard moving back and forth. Any tighter and the keyboard supports start to move to the side which could mess up the positioning.

Connect the keyboard cables together and then place the upper case down. At this point I had to make a small adjustment the to the horizontal alignment of the keyboard as the Amiga’s LEDs were not quite central in the case holes. The only other adjustment needed was a very slight upwards bend on the LEDs, again to get them central in their case holes.

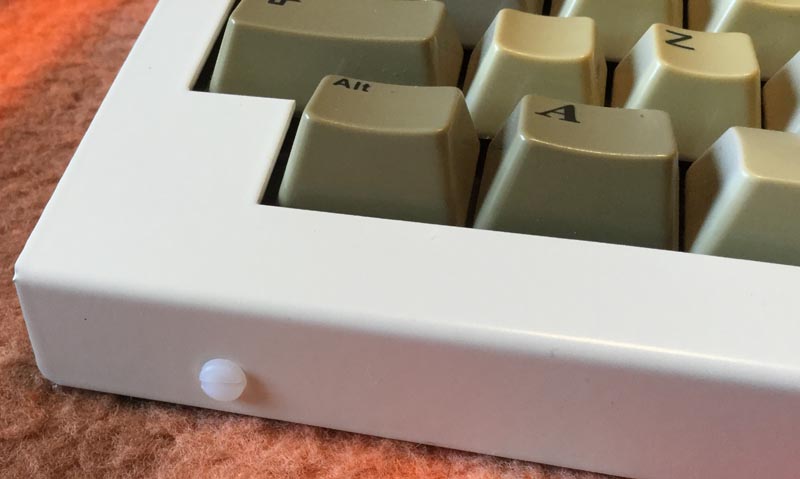

The case is held together by Nylon screws. I don’t know how rugged these are but they hold the whole thing together very well. They look a lot better than regular screws would and should they fail they are easily replaced.

In the picture below you can just see the LEDs are recessed in the case slightly and you will notice the overhang of the upper case half.

The keyboard is done. It is pretty robust but I feel that you would want to take care and not place too much weight on it. Under normal use it should be fine. There are 4 soft feet fitted to the underside, as there is on the main case itself.

The keys have yellowed slightly over the years and I will be fitting a new set of key caps once A1200.net ship them out.

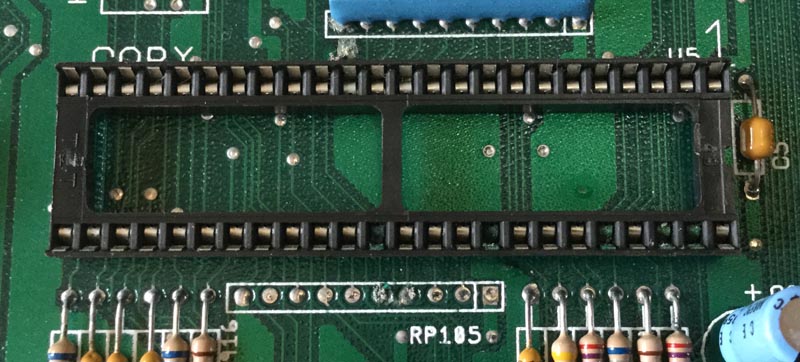

Cleaning the Motherboard

I have never had to wash a PCB before and the thought of pouring liquid over my Amiga sets off alarm bells in the brain (despite the request for coffee to be poured through the vents during Cannon Fodder). I always find researching this sort of thing a pain as you can get conflicting advice. When you think you have settled on a plan somebody else makes you think again! I’d like to thank Discord users Neil and Laurent from the Amigos Retro Gaming channel for their advice. I went with your instructions.

The spots of corrosion were centred around the location of the old battery. I removed the nearest removable chips as I was going to concentrate the clean around there but the whole thing would be given a clean. My given instructions meant I would need to wash the board with white vinegar to neutralize any leaked battery fluid, use distilled water to clean all that off and then finish off with some IPA. I used a light brush to help the vinegar get to as much off the board as possible. I then carefully flushed with distilled water, allowed as much of that to run off as possible and then flushed again with IPA. Carefully shaking and leaving in the warm sun and slight breeze to get the board visually dry.

Yes, we do get sun in the UK and the day was perfect. Of course you need to be sure the board is 100% dry before continuing and so I bought the board indoors and placed it in front of a cool fan for a couple of hours. I then had an idea. When my PC is on and busy it produces a fair amount of warm air, some of which is blown out of the top of the case. Perfect to ensure the board is totally dry.

The next day I repopulated the board and the build could continue.

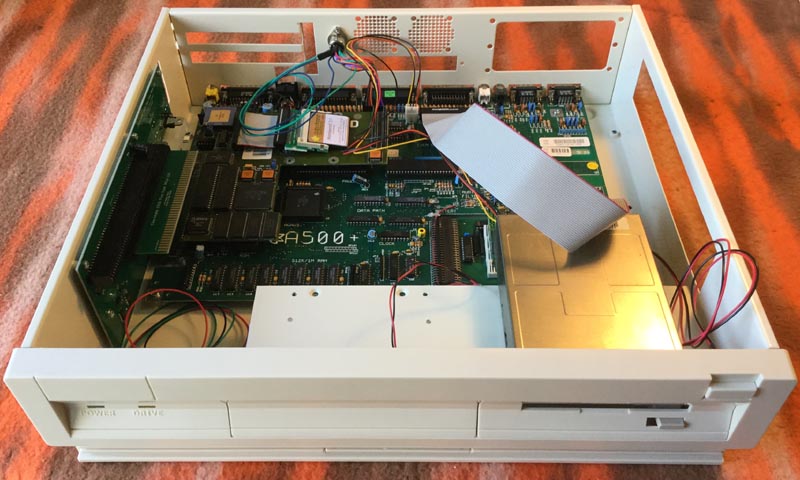

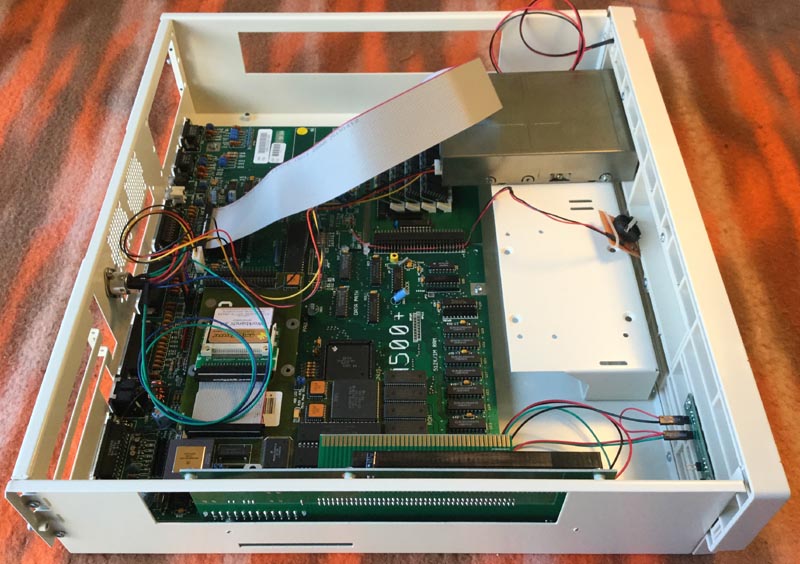

Installing the motherboard

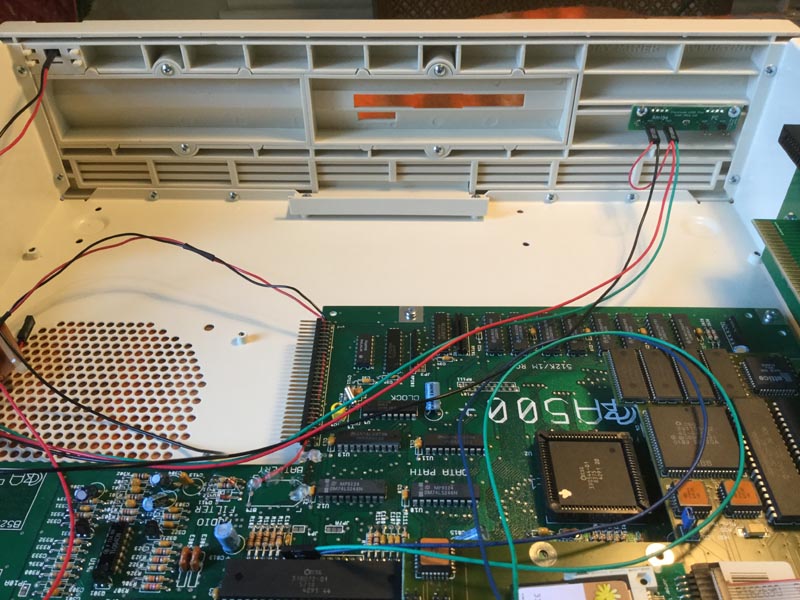

The manual recommends connecting the Zorro Interface before placing the motherboard into the case.

The first time you do this you can work out where to place the supplied motherboard risers. Only screw in the risers into the holes designated for your motherboard otherwise you risk a short circuit. If you feel you need extra support then locate some rubber feet or similar. For the record, I found the standard supports to be sufficient. The drive mounting platform was removed for this. Everything screwed down without any issue. The mounting points are very accurate. Once I knew the motherboard would be held properly I removed it again.

Mounting the Floppy Drive and Fitting the Trapdoor Expansion

The drive mounting plate it held in place by 4 screws which pass through the bottom of the case. I intend for this to hold one floppy drive and one CD drive but for now I will start with just the floppy. 4 more screws hold the drive in place. I decided to mount the drive in the right hand bay which meant I needed to swap the fascia plates on the front of the case. Longer floppy cables are required, the standard Amiga cables aren’t suitable for either bay.

The drive eject button is not central in the cut out but the disk slot is positioned correctly. I assume that the eject button cut out is larger to ensure a range of drives can fit. It doesn’t look great but I can live with it and who knows, maybe a replacement fascia can be 3D printed.

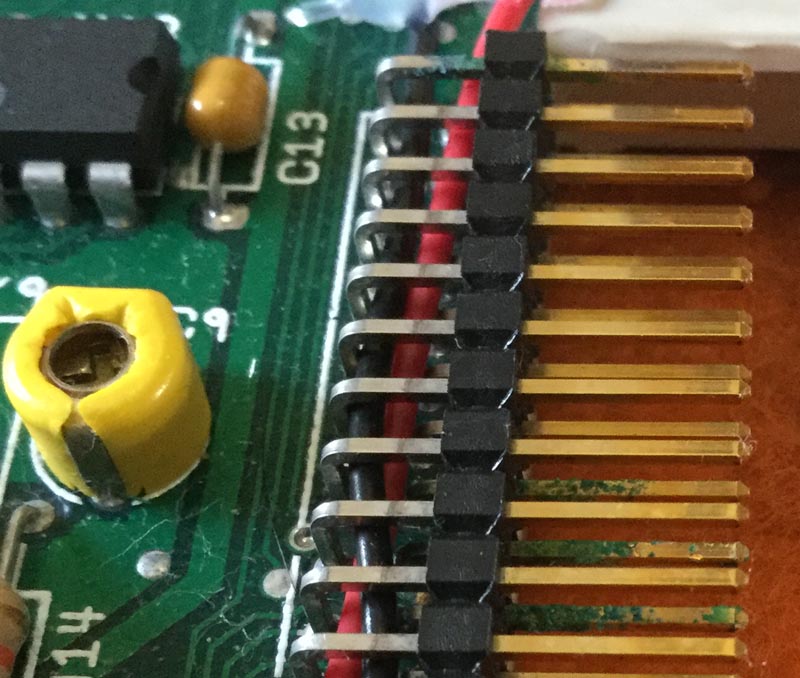

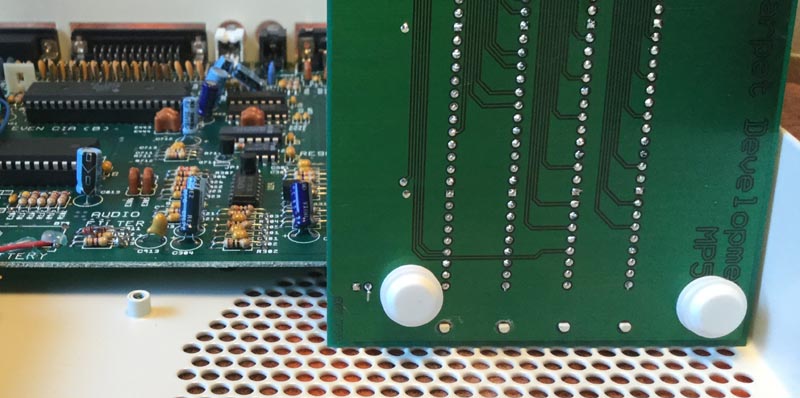

When I test fitted the trapdoor expansion I found that while the connector holds the board securely in place there is no other support at all. Two layers of stick on rubber feet do the trick.

Current thoughts and what next

In part 1 I noted some text on the Zorro Interface board that may have implied that I wouldn’t be able to use anything other than the ACA accelerator cards. I asked about using my Alfapower hard drive/memory expansion and Stephen Jones and Rob Cranley were kind enough to answer and said that there shouldn’t be an issue. Just in case you didn’t know, Stephen designed the case and Rob designed the Interface boards.

However, while sitting at the table my mind has flagged a possible issue. Not with compatibility but with available space in the case. My current CD drive is a full size drive and while that should fit into the other drive bay I don’t think the Alfapower card will fit in the space that remains. This means that my options are to fit the Alfapower card and keep the CD drive external or to lose the Alfapower card and its extra RAM and see if I can get the CD drive to work with the Viper 520CD accelerator’s IDE interface (something that I have tried before and had no luck). The third option is to get a slim CD drive and cross my fingers that it will fit with the Alfapower card. If none of these options work then this case might be pointless for me.

I also need to work out if I can use the case mounted power and hard drive access LEDs.

Click here for Part 3 – PSU and DVD Drive